Products » Bevel Helical & Shaft Mounted Gearbox

Bevel Helical & Shaft Mounted Gearbox

Series-T

Built in 9 sizes with 2 reduction stages and in 8 sizes with 3 reduction stages.

Three input types are available : projecting input shaft, pre-engineered motor coupling (bell and joint) and pre-engineered COMPACT motor coupling. (Sizes 56 and 63 excluded). the three input types can be mounted either vertically and/or horizontally.

Gear unit casing in aluminium alloy GAlSi9Cu1 UNI7369/3 (56-63), in engineering cast iron, EN GJL 200 UNI EN 1561 (71-180) or spheroidal graphite cast iron EN GJS 400-15 U UNI EN 1563 (200-225), it is ribbed internally and externally to guarantee rigidity. It is machined on all surfaces for easy positioning. The single lubrication chamber guarantees improved heat dissipation and improved lubrication of all the internal components.

Gears are built in casehardened compound steel and have undergone case-hardening and quench-hardening treatments. In particular, the first reduction stage consists of two GLEASON spiral bevel gears with precision ground profile, in 16CrNi4 or 18NiCrMo5 UNI7846 case-hardened and quench-hardened steel.

The use of high-quality tapered roller bearings on all shafts (except for the input sleeve on the pre-engineered compact motor coupling, which is supported by angular ball bearings) ensures long life and enables very high external radial and axial loads.

The standard hollow output shaft made of steel (shrink disc available on request), the option of mounting an output flange on one or both sides and the possipility of mounting a backstop device make these gear units extremely versatile and easy to install.

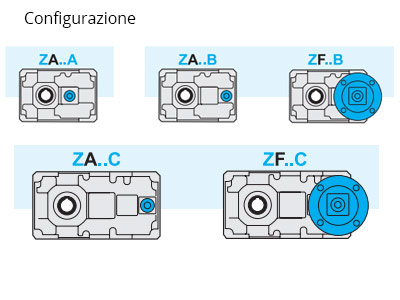

Series-Z

Built in 6 sizes with single reduction stage, in 6 sizes with two reduction stages and in 6 sizes with three reduction stages.

Two input types are available : with projecting input shaft, with pre-engineered motor coupling (bell and joint).

Gear unit body in engineering cast iron, EN GJL 200 UNI EN 1561 (71-180) or spheroidal graphite cast iron EN GJS 400-15U UNI EN 1563 (200-225). It is ribbed internally and externally to guarantee rigidity it is machined on all surfaces for easy positioning. The single lubrication chamber guarantees improved heat dissipation and better lubrication of all the internal components.

The helical spur gears are built in 16CrNi4 or 18NiCrMo5 UNI7846 quench-hardened and case-hardened steel. The first stage is ground.

The use of high-quality tapered roller bearings on all shafts ensures long life, and enables very high external radial and axial loads.

The standard hollow output shaft made of steel (shrink disc available on request), the option of mounting an output flange on the side opposite to the input shaft the possibility of mounting a backstop device make these gear units extremely versatile and easy to install.

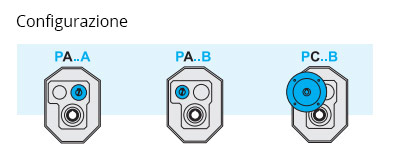

Series-P

Built in 6 sizes with a single reduction stage and in 6 sizes with two reduction stages.

Two input types are available: one with projecting input shaft and one with compact motor coupling for mounting to IEC flanged electric motors.

Gear unit body in engineering cast iron, EN GJL 200 UNI EN 1561 ribbed internally and externally to guarantee rigidity The single lubrication chamber guarantees improved heat dissipation and better lubrication of all the internal components.

The helical spur gears are built in 16CrNi4 or 18NiCrMo5 UNI7846 quench-hardened and, case-hardened steel. The first stage is ground.

The standard hollow output shaft made of steel and available with holes of various diameters, the possibility of mounting an output flange on the side opposite the input shaft, anchorage through either a tensioner or a torque arm, the possibility of mounting a backstop device, make these gearboxes highly efficient and facilitate their installation in various applications.

Series-M

Available in 7 sizes with two reduction stages, shaft-mounting occurs by means of tension arm. A back-stop device can also be mounted if required by the application.

A projecting input shaft with key is available for mounting of pulleys for belt transmissions.

The helical spur gears are built in 20MnCr5 UNI7846 quench-hardened and case-hardened steel. The teeth of all gears are ground in order to ensure silent running.

The standard hollow output shaft made of steel is dimensioned accordingly to enhance performance in all different applications.

The rigid structure of the housing in engineering cast iron ensures superior resistance to stress. The single lubrication chamber guarantees excellent thermal dissipation.

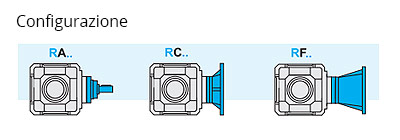

Series-R

Built in five sizes with three types of output shaft : hollow, projecting or double-extended. Moreover, an additional output shaft can be installed opposite the input shaft.

Three input types are available : with projecting input shaft, with pre-engineered motor coupling (bell and joint) and pre-engineered COMPACT motor coupling.

Gear unit body in engineering cast iron, EN GJL 200 UNI EN 1561 ribbed internally and externally to guarantee rigidity and machined on all surfaces for easy positioning. The single lubrication chamber guarantees improved heat dissipation and better lubrication of all the internal components.

The mechanism of these gearboxes consists of two GLEASON spiral bevel gears with precision ground profile, 16CrNi4 or 18NiCrMo5 UNI7846 steel.

The use of high-quality tapered roller bearings on all shafts (except for the input sleeve on the compact motor coupling, which is supported by angular ball bearings) ensures long life, and enables very high external radial and axial loads.

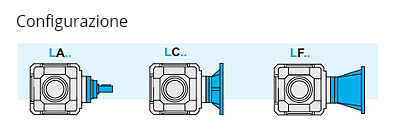

Series-L

Built in 5 sizes with three types of output shaft : hollow, projecting or double-extended. Moreover, an additional output shaft can be installed opposite to the input shaft.

Three input types are available : with projecting input shaft, with pre-engineered motor coupling (bell and joint) and pre-engineered COMPACT motor coupling.

Gear unit body in engineering cast iron, EN GJL 200 UNI EN 1561 ribbed internally and externally to guarantee rigidity and machined on all surfaces for easy positioning. The single lubrication chamber guarantees improved heat dissipation and better lubrication of all the internal components.

The mechanism of these gearboxes consists of two GLEASON spiral bevel gears with precision lapped profile, 16CrNi4 or 18NiCrM05 made of steel.

The use of high quality bearings on all the axis ensures long life to the gearbox and allows very high radial and axial loads.

Gearbox housing, flanges, bells and covers are externally painted with BLUE RAL 5010.